Få kännedom om dina branschbehov → Bekräfta produktparametrar → Erbjuda anpassade lösningar → Lämna en offert → Erbjud gratis provtestning

📊 Regulatoriska data visar att främmande ämnen är en av de främsta orsakerna till icke-kompatibla livsmedel. 🚫

❌ Manuella stickprov är opålitliga och säkerställer inte efterlevnad för hela partier, vilket lämnar dig öppen för regulatoriska påföljder. ⚖️

📦 Ogenomskinlig förpackning och höghastighetslinjer förhindrar visuell inspektion 👁️❌. Alla problem som upptäcks efter öppning orsakar oåterkallelig varumärkesskada. ⚠️

Precision Metalldetektor

Denna detektor identifierar exakt ferro, icke-järn , och rostfritt stål, metaller med ett känslighetsintervall på 0,3 mm till 1,0 mm. Den styrs via en touchskärm som erbjuder datainspelning och spårbarhetsfunktioner.

Dynamisk Vägningsteknik

Ger högpresterande noggrannhet inom ±0,1–0,5 gram . Systemet automatiskt avvisar icke-konformant produkter samtidigt som det ger viktkontroll i realtid.

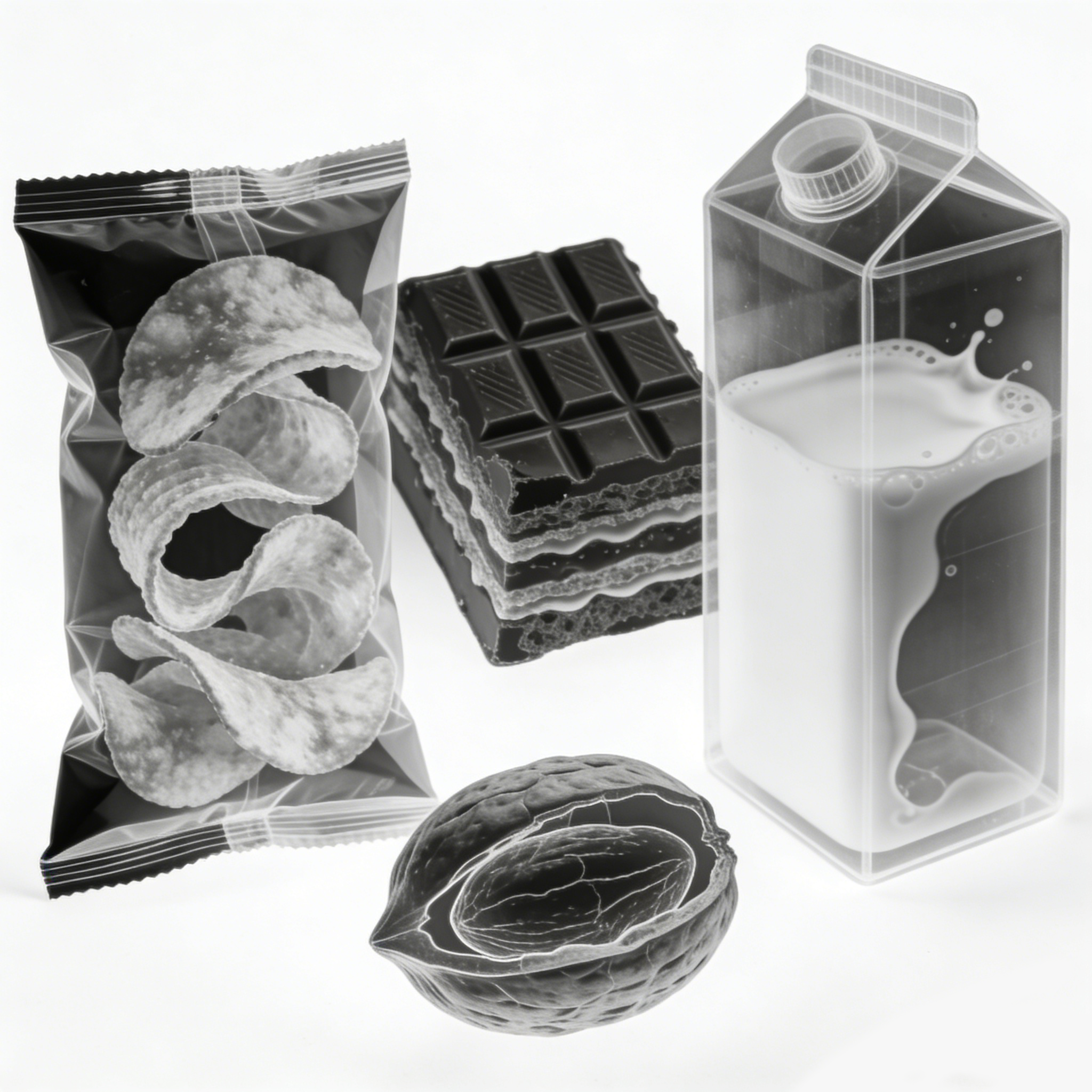

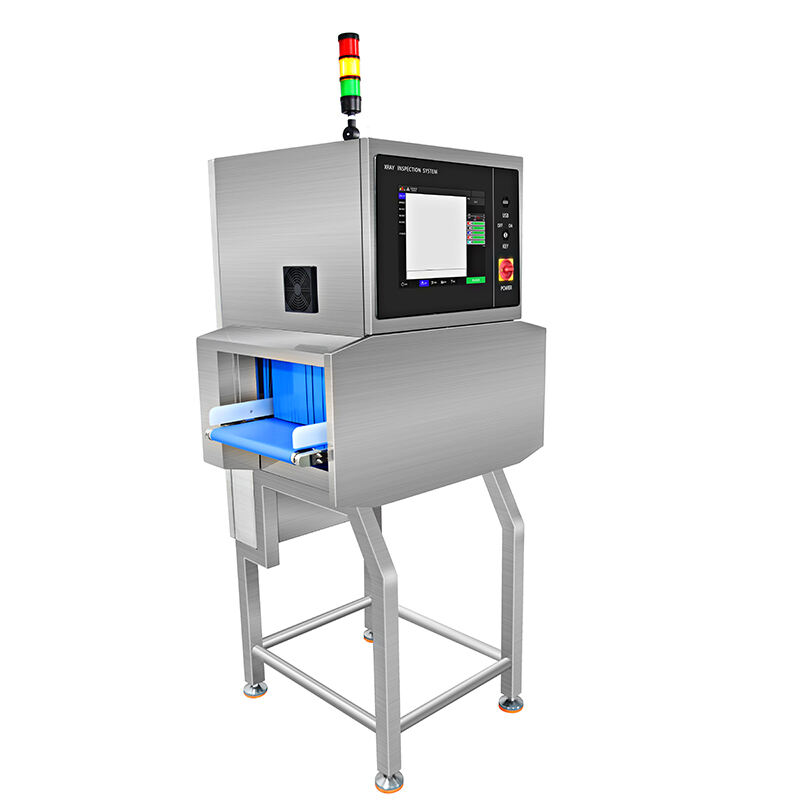

X-strålsystem för inspektion

Ger omfattande inspektion genom att upptäcka samtidigt metaller, glas, stenar och högdensitetsplaster . Den erbjuder hög känslighet för föroreningar så små som 0,3 mm stödda av realtidsbilder och dataspårbarhet.

Produktionslinjen hos ett visst dryckesföretag har upprepade gånger misslyckats med att effektivt upptäcka metallfragment i råvaror och metallspån orsakade av utrustningsnötning, vilket resulterat i en förlust på cirka 15 arbetstimmar per månad.