Obtain your industry needs → Confirm product parameters → Provide customized solutions → Offer a quotation → Provide free sample testing

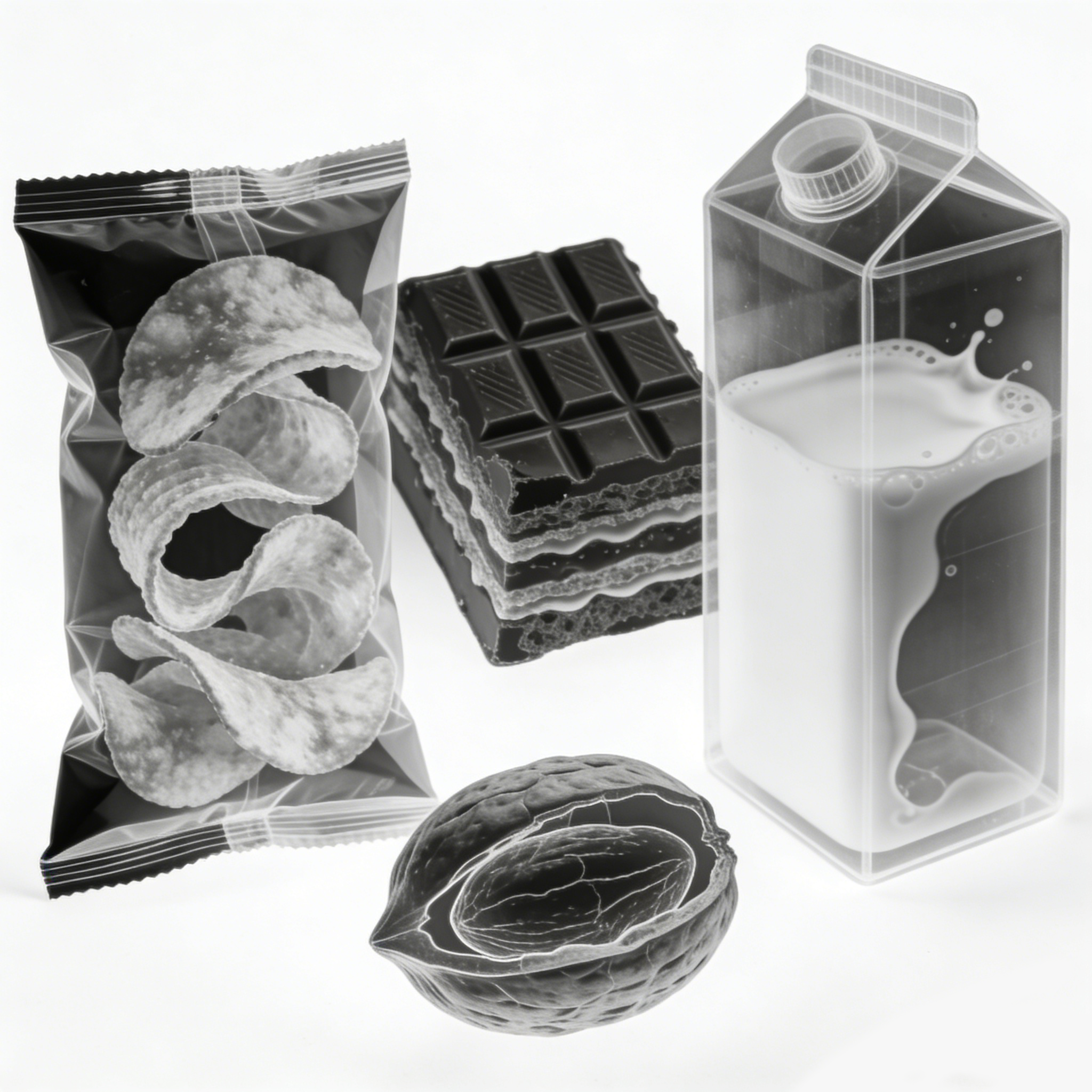

📊 Regulatory data shows foreign matter is a top cause of non-compliant food. 🚫

❌ Manual spot checks are unreliable, failing to ensure full batch compliance and leaving you open to regulatory penalties. ⚖️

📦 Opaque packaging and high-speed lines prevent visual inspection 👁️❌. Any issue found after opening causes irreversible brand damage. ⚠️

Precision Metal Detector

This detector accurately identifies ferrous, non-ferrous, and stainless steel,metals with a sensitivity range of 0.3 mm to 1.0 mm.It is controlled via a touchscreen that provides data recording and traceability functions.

Dynamic Weighing Technology

Delivers high-precision accuracy within ±0.1–0.5 grams. The system automatically rejects non-conforming products while providing real-time weight monitoring.

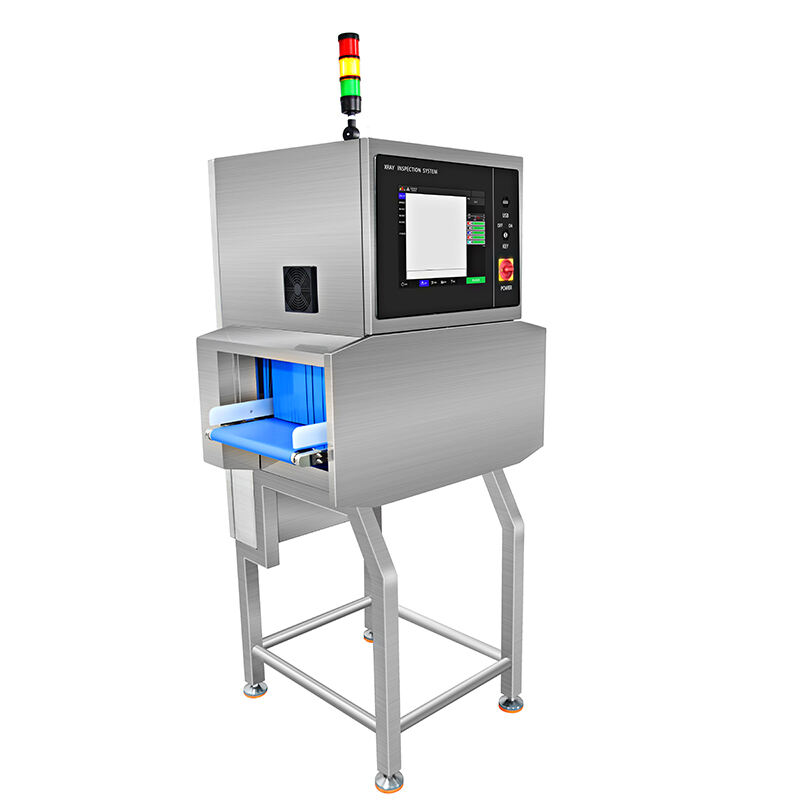

X-ray Inspection System

Provides comprehensive inspection by simultaneously detecting metals, glass, stones, and high-density plastics. It delivers high sensitivity for contaminants as small as 0.3 mm supported by real-time imaging and data traceability.

The production line of a certain beverage company has repeatedly failed to effectivelydetect metal fragments in raw materials and metal shavings caused by equipment wear,resulting in an approximate loss of 15 working hours per month.