Მომატებული სასმელების წარმოების ინდუსტრიაში, პროდუქციის ხარისხი და უსაფრთხოების მოთხოვნებთან შესაბამისობა წარმოადგენს მიმზიდველობის საშუალებას ბაზარზე კონკურენტუნარიანობის დასამყარებლად

Კონსერვირებული სასმელების წარმოებაზე ორიენტირებული დიდი მასშტაბის სასმელების საწარმო, რომელიც მომხმარებლის უსაფრთხოებასა და ბრენდის რეპუტაციას თავისი არსებობის საფუძვლად მიიჩნევს, კარგად აქვს გააზრებული, რომ მხოლოდ იმ ხარისხის კონტროლის სისტემის შექმნით, რომელიც აღემატება სამრეწველო სტანდარტებს, შეუძლია დაუპირისპირდეს მკვეთრ კონკურენციას. სავსების სიზუსტისა და ლითონის მინარევების ორმაგი გამოწვევის წინაშე, ინტელექტუალური სისტემის შემოტანა, რომელიც აერთიანებს მაღალი სიზუსტის საწონ კონტროლს და ლითონის მინარევების აღმოჩენას, არა მხოლოდ რეგულატორული მოთხოვნების შესაბამისობის აუცილებელი ზომაა, არამედ მომხმარებლის მიმართ ჩვენი ვალდებულების ღვთისმშენელი შესრულება.

Ამჟამინდელი პრობლემა: ტრადიციული ხარისხის შემოწმების მოდელები სერიოზულ გამოწვევებს უბრუნდებიან

Ამჟამად კონსერვის წარმოების მაღალსიჩქარე ხაზების ექსპლუატაციის დროს ტრადიციული ხელით ნიმუშების აღების მეთოდი უკმარისობის ნიშნები აჩვენებს:

Გაზომვის სიზუსტის უზრუნველყოფის სირთულე: შევსების მოცულობის შეცვლით გამოწვეული წონის გადახრები არ იწვევს მხოლოდ პირდაპირ მომხმარებლის საჩივრებს, არამედ გამოავლინს საწარმოებს *წინასწარ დაფასოებული საქონლის გაზომვის მონიტორინგისა და ადმინისტრირების ზომების შესაბამისობის რისკებს, რაც საწარმოებისთვის ორმაგ წნეხს ქმნის.

მუდმივი უსაფრთხოების საფრთხეები: თუ კონსერვის დამუშავებისას და აპარატურის მომსახურებისას მეტალის ნაწილაკები (რკინა, არარკინის, ღირკალი ფოლადის და ა.შ.) დროულად არ გამოივლინება, შეიძლება გამოიწვიოს მასშტაბური საკვების უსაფრთხოების შემთხვევები და მოახდინოს კატასტროფული ზიანი საწარმოს რეპუტაციაზე.

Ეფექტიანობის შეზღუდვების გადალახვის წინაშე დგახართ: ხელით შემოწმების სიჩქარე ვერ ჰყვება წუთში ასობით კონსერვის წარმოების რითმს, რაც მაღალ გამოტოვების მაჩვენებლამდე მიიყვანს. ამასთან, სამუშაო ხელფასის მუდმივად მატება კიდევ უფრო ამცირებს საწარმოს მოგების მაჩვენებელს.

Მონაცემთა სილოსები, რომლებიც ზღუდავენ განვითარებას**: ინსპექტირების ფრაგმენტული მონაცემები ვერ ქმნის ეფექტურ ხარისხის თვალსაჩინოების ჯაჭვს, ხოლო პროცესების ოპტიმიზაცია არ აქვს მონაცემთა მხარდაჭერა, რაც ზღუდავს საწარმოო ხაზების ინტელექტუ

Ინოვაციური გადაწყვეტა: ინტეგრირებული ინტელექტუალური გამონახვის სისტემა

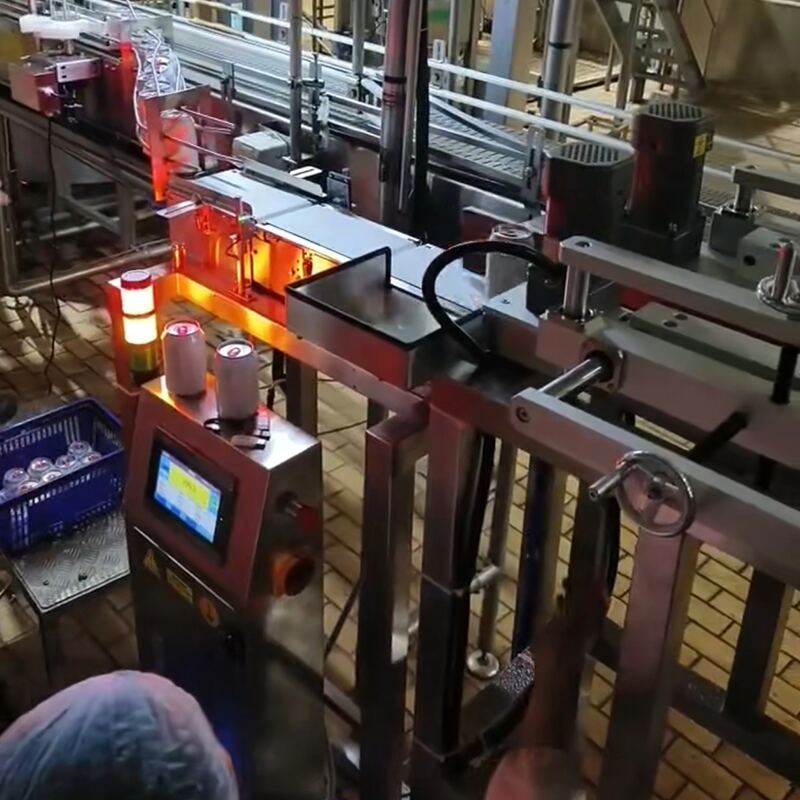

Ზემოთ აღნიშნული პრობლემების გადასაჭრელად, გუანდუნის ივან ტესტირების ტექნოლოგიის კომპანია ლტდ.-მ სპეციალურად შექმნა მაღალი სიმძლავრის სისტემა, რომელიც ინტეგრირებულია ავტომატურ საწონ და მეტალის აღმოჩენის ფუნქციებთან. ეს ამოხსნა, რომელიც სპეციალურად შეიმუშავებულია მაღალი სიჩქარის კონსერვის წარმოების ხაზებისთვის, ახორციელებს მთელი პროცესის ავტომატიზაციას „აღმოჩენიდან - სორტირებამდე - მონაცემთა მართვამდე“ და ქმნის მყარ ხარისხის დაცვის ქსელს.

Სისტემის ძირითადი უპირატესობები: სიზუსტე, ეფექტურობა და ინტელექტი

1. ზუსტი აღმოჩენა ორმაგი დაცვით

Სისტემა კომპლექტდება საერთაშორისო ლიდერ საწონ სენსორებით, რომლებიც აღწევენ ±0.1გ-მდე ზუსტობას, რათა უზრუნველყოს თითოეული თეჯვის სინამდვილის ზუსტი კონტროლი. ამასთან, ინტეგრირებული მრავალსიხშირიანი მეტალის აღმოჩენის მოდული შეუქმედავად ამოიცნობს ძალიან პატარა მეტალის მიმაგრებებს φ0.3მმ-მდე (შესაბამისი ადამიანის თმის დიამეტრს), რაც ქმნის მყარ ბარიერს პროდუქის უსაფრთხოებისთვის.

2. სწრაფი რეაგირება შეუფერხებელი ინტეგრაციით

200 თეჯვის წუთით დამუშავების შესაძლებლობით, იდეალურად ემთხვევა სიჩქარის წარმოების ხაზების რითმს. ორიგინალური „აღმოჩენა გადაადგილებისას“ სამუშაო რეჟიმი ერთდროულად უზრუნველყოფს წონის შემოწმებას და მეტალის აღმოჩენას, რაც თავიდან აცილებს ეფექტიანობის დაკარგვას, რომელიც გამოწვეულია ტრადიციული სეგმენტირებული აღმოჩენით.

3. ინტელექტუალური დახარისხება Lean მენეჯმენტისთვის

Ხელოვნური ინტელექტის ალგორითმზე დაფუძნებული ინტელექტუალური სორტირების სისტემა ზუსტად არიცხავს დაუშვებელ პროდუქებს პროდუქტები მილიწამებში. ეს უზრუნველყოფს დამზადებული პროდუქტების 100%-იან შესაბამისობას და ასევე ეკონომიას უზრუნველყოფს მასალების ათასობით იუანით წელიწადში, ზედმეტი ჩასხმის კონტროლის შედეგად.

4. მონაცემთა გაძლიერება სრული პროცესების თვალყურის დევნისათვის

Შეიცავს მრეწველობის დონის ინტელექტუალურ პანელს, რომელიც საწარმოს ოპერაციის სტატუსსა და ხარისხის ტენდენციებს ასახავს რეალურ დროში. ასევე სრულად არქივში აქცევს თითოეული კონსერვის თავისუფალ ფაილს და უზრუნველყოფს შესაბამისობის ანგარიშების ერთი დაჭერით გენერირებას FDA და HACCP-ს მსგავსი სერთიფიკაციის აუდიტების მარტივად გასატარებლად.

5. მოქნილი დიზაინი, რომელიც უდარდელად იმუშავებს

Მოდულური სტრუქტურა უზრუნველყოფს მოწყობილობის სწრაფ გაშლას, ხოლო საწარმო ხაზის ინტეგრაცია შეიძლება დასრულდეს უმეტეს 8 საათში. ინტელექტუალური თვითდიაგნოსტიკის სისტემა ადრე განაცხადებს პოტენციურ გამუდმებებზე, ხოლო შემდეგი გამუდმების საშუალო დრო (MTBF) აღემატება 3000 საათს, რაც უზრუნველყოფს უწყვეტი წარმოების საიმედო მხარდაჭერას.

Განხორციელების შედეგები: ხარისხისა და ეფექტურობის ორმაგი ნახტომი

Სისტემის გამოყენების შემდეგ, საწარმომ მნიშვნელოვანი გაუმჯობესება მიაღწია რამდენიმე მიმართულებით:

Ხარისხის ინდიკატორების მნიშვნელოვანი გაუმჯობესება: მომხმარებელთა საჩივრების მაჩვენებელი შემცირდა 82%-ით, პროდუქციის პირველი კვალიფიკაციის მაჩვენებელი 99.95%-ზე მაღალია, ხოლო მომხმარებელთა კმაყოფილების კვლევებში "ზუსტი გაზომვის" ქულა 35%-ით გაი

Ოპერაციული ეფექტიანობის შესაძლებლობების გადალახვა: წარმოების ხაზის სრული ეფექტიანობა 32%-ით გაიზარდა, ხარისხის შემოწმების პოზიციები 40%-ით იქნა ოპტიმიზირებული, ხოლო წლიური შრომის ღირებულების ეკონომია ერთ მილიონ იუანზე მეტი გახდა.

Პროცესული დონის მუდმივი ოპტიმიზაცია: რეალურ-დროში აღმოჩენის მონაცემებზე დაყრდნობით, შევსების სიზუსტის სტანდარტული გადახრა 0,8 გ-დან 0,3 გ-მდე იქნა ოპტიმიზირებული, ხოლო წლიური ნედლეულის დანახარჯი დაახლოებით 25%-ით შემცირდა.

Მარტივი შესაბამისობის მართვა: შექმნილ იქნა სრულყოფილი ხარისხის თვლადობის სისტემა, რომელიც წარმატებით გაიარა რამდენიმე გაფრთხილების გარეშე ჩატარებული შემოწმები და იქცა ხარისხის მართვის მიმდევარ საწარმოთა ეტალონად.

Პროექტის წარმატებით განხორციელებამ სრულიად დაადასტურა გუანდუნის ივან ტესტირების ტექნოლოგიის კომპანიის ღრმა გამოცდილება საკვებისა და სასმელების ხარისხის კონტროლის სფეროში. ეს ინტეგრირებული საწონ-სამეტალო დეტექტორული სისტემა არა მხოლოდ ამოხსნის საწარმოს ამჟამინდელ ხარისხის კონტროლის პრობლემებს, არამედ მონაცემებზე დაფუძნებული მიდგომებით უზრუნველყოფს უწყვეტ გაუმჯობესების ახალ გზებს. ის გახდა საწარმოს ხარისხის სისტემის გამოცვლის შეუძლებელი „ინტელექტუალური კარი“, რომელიც მუდმივად ქმნის ღირებულებას რისკების შემცირებით, ეფექტიანობის ამაღლებით და ბრენდის გაძლიერებით, მისი უნიკალური ხარისხობრივი კონკურენტული უპირატესობით მკვეთრ ბაზარზე.

Მომავალში ჩვენ განვათავსებთ ტექნოლოგიურ ინოვაციებს, ინტერნეტის და დიდი მონაცემების ახალ ტექნოლოგიების სიღრმისეული ინტეგრაციით ტესტირების მოწყობილობებთან, რათა დავეხმაროთ უფრო მეტ საკვებისა და სასმელის საწარმოებს ხარისხის მართვის ციფრულ ტრანსფორმაციაში და ერთად დავიცვათ „ჩინეთში დამზადებულის“ ხარისხის პრინციპი.