X-rays work through electromagnetic radiation that can pass through materials depending on how dense they are and what atoms they contain. The way X-rays penetrate stuff changes from material to material, which helps spot differences between regular packaging and unwanted contaminants inside. Take something dense like metal for example it needs much more energy to get through compared to lighter materials. Research shows that thick metal objects really demand higher energy settings if we want complete penetration, which is why proper calibration matters so much for good results. Getting the calibration right means adjusting X-ray equipment specifically for whatever material we're looking at, and this makes finding contaminants much more accurate in practice.

The way different materials pack together matters a lot when it comes to spotting contaminants in X-ray scans. Food product scans rely on density measurements to tell what's going on inside, which helps find those unwanted bits mixed in. Glass and stainless steel show up differently because they don't all weigh the same per volume. Take stainless steel versus glass for instance – since steel packs tighter, it shows up darker on scans and stands out more clearly. Studies have found that looking at these density contrasts boosts detection success rates somewhere around 90% in food safety work. Getting comfortable with these material differences really makes a difference in catching contamination accurately.

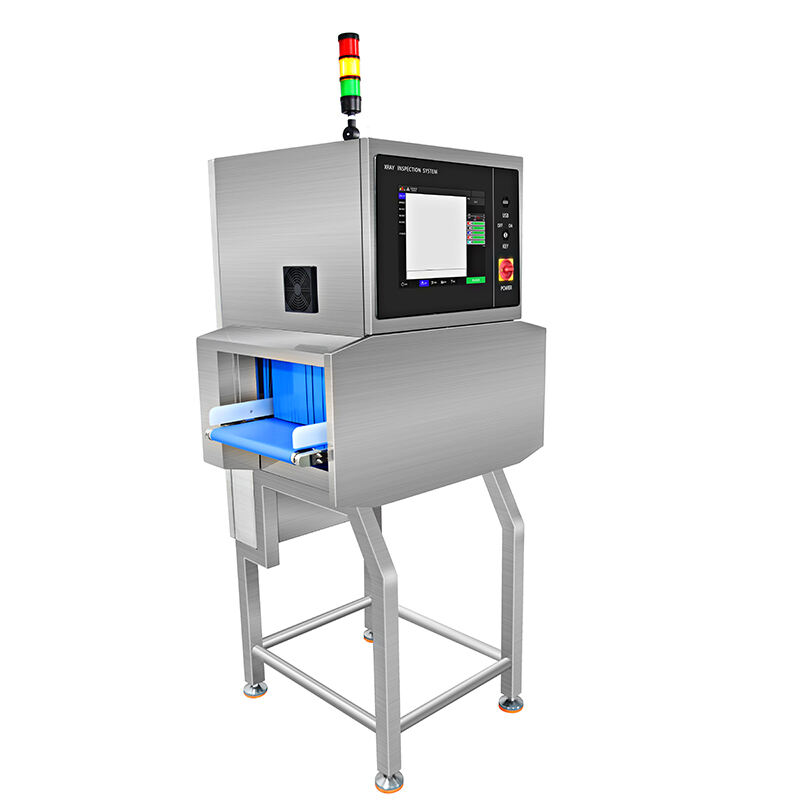

Today's X-ray equipment relies on sophisticated sensors to turn those invisible X-ray photons into actual pictures, which helps analysts get a clearer look at what's inside scanned items. Inside these machines, special sensors catch the energy that passes through objects and turn them into something we can see, letting inspectors spot foreign substances much faster than before. Behind the scenes, image processing software does a lot of heavy lifting to sharpen up those images and make sure even small details stand out clearly. Many food producers are now turning to dual-energy X-ray technology because it gives them better results when trying to tell apart various ingredients during quality checks. With this upgraded system, operators can easily differentiate between metal fragments, glass shards, and other unwanted materials mixed in with food products, leading to safer packaging lines across the industry.

In manufacturing environments, metal contaminants like stainless steel and aluminum show up all the time because they're so dense that X-ray machines can spot them pretty easily. According to recent research, around three quarters of all contaminant finds in packaged foods actually turn out to be metal bits. Getting those detection systems properly tuned matters a lot when it comes to telling one type of metal from another without missing anything important. Food processors set their equipment differently depending on what kind of metal they're looking for, which helps catch problems before they reach consumers. This attention to detail keeps food safe for eating and meets regulatory requirements at the same time.

Food processors face serious problems when glass and stone particles get mixed into products during manufacturing. That's why many facilities invest in good X-ray detection equipment these days. These machines actually spot foreign objects by looking at their density differences compared to food items. For instance, they catch those tiny pieces of glass that might slip through other inspection methods. High density plastics used in packaging materials also present hidden dangers. Modern X-ray systems scan for all sorts of contaminants including these tough plastics, which meets what most regulatory bodies require nowadays. Companies that detect issues early on tend to avoid expensive product recalls down the road. And let's be honest, keeping customers confident about food safety matters just as much as meeting legal requirements.

In meat processing plants, bones are pretty much everywhere and pose a real problem as organic contaminants. X-ray systems need to pick them up quickly but this isn't always straightforward. Ceramics present their own headaches because they come in different densities. Sometimes regular imaging just won't cut it, so manufacturers have to bring out the big guns with special tech to spot those tricky materials. Then there's rubber stuff too which gets missed quite often despite being dangerous if ingested. Advanced screening equipment actually works well for catching these rubber bits though. Putting together solid detection procedures for all these different types of contaminants is crucial for keeping products safe from harmful stuff that slips through unnoticed.

Standard X-ray inspection systems aren't great at spotting things like hair strands or thin plastic bits because they just don't stand out enough against regular food stuffs. The problem is these items have almost the same density as what's around them, so they basically blend right into those gray scale images we get from X-rays. Some actual testing in production environments shows detection success rates sometimes fall under half for these tricky contaminants, which really points out how limited our current tech still is. Companies trying to fix this issue typically look at two main approaches: either boosting the sensitivity settings on their existing X-ray equipment or adding extra checks alongside it. Metal detectors work well for certain things, while visible light inspection adds another layer of protection. Most smart manufacturers combine several different methods anyway since relying solely on one technique rarely gives complete coverage when it comes to keeping products safe for consumers.

Finding organic contaminants with X-ray systems isn't easy because these contaminants often have very similar density levels as the actual food products they're mixed with. When this happens, the detection software needs regular upgrades just to tell what's contaminant and what's product during scans. Studies show that companies really need to bring together different technologies alongside X-rays if they want to solve this problem properly. Some are already mixing in UV or IR sensors along with their X-ray equipment. This combination works much better for catching those tricky organic contaminants. Food manufacturers who invest in multiple detection methods see fewer contamination issues down the line, which means safer products for consumers overall.

X ray inspection systems have one major drawback when it comes to finding tiny bits of contamination. The truth is, anything smaller than about 1mm often slips right past regular X ray scans without anyone noticing. This problem really highlights why we need better tech for these machines if we want to close those detection loopholes. The good news? The industry is working hard on solutions. We're seeing things like sharper images and smarter computer programs being developed all the time. These upgrades should help spot those little troublemakers that currently get missed. For food producers, investing in these improvements means fewer false negatives and safer products reaching consumers' tables. While implementing new tech always takes time and money, many companies see it as essential for maintaining trust in their brand.

When X-ray systems get combined with metal detectors, food safety operations see a major improvement in spotting contaminants. The thing about X-rays is they catch all sorts of stuff metal detectors miss out on detecting metals but also non-metallic materials too. Metal detectors still have their place though since they're really good at finding those pesky metal bits. Throw in some checkweighers into the mix and suddenly there's another checkpoint for quality control. These devices verify if products weigh what they should be, keeping things consistent across batches. Industry reports show companies using this combo approach tend to find contaminants more effectively than those relying on single technology solutions. Putting metal detectors, checkweighers, and X-ray machines together creates something pretty solid for handling different kinds of contamination risks while making sure the end product stays within spec requirements.

Adding X-ray inspection to HACCP protocols really boosts compliance with food safety rules. These X-ray systems act as important safety gates in production lines, catching things like metal fragments or glass shards that might slip through other checks. Real world data shows that facilities using X-ray tech report fewer contamination incidents compared to those relying solely on traditional methods. The push for better quality control isn't just coming from regulators either – recent surveys indicate manufacturers are voluntarily raising their own standards when it comes to managing potential hazards. With consumers demanding safer products than ever before, many companies find that incorporating X-ray technology into their HACCP plans makes good business sense while meeting evolving regulatory expectations across the food industry.

Where X-ray systems are placed along the production line makes all the difference when it comes to getting accurate readings and running things smoothly. Putting them in the right spots actually boosts how good they are at spotting those pesky contaminants that slip through. Most experienced operators will tell you to position X-ray machines where they work best with how products move through the line and alongside other inspection equipment. We've seen time and again that when these systems are properly located, they cut down on those annoying false rejections which means less waste and better overall product quality. Getting the placement right so it matches what happens naturally on the production floor really helps catch contaminants before they become problems, giving manufacturers an extra layer of protection against food safety issues down the road.

X-ray systems for detecting foreign objects in food can spot all sorts of unwanted stuff like bits of metal, broken glass, and small plastic fragments that might end up mixed in during production. The technology behind these machines allows them to catch these problems fast and accurately, which helps prevent dangerous situations down the line when food reaches consumers. Food processors rely on these systems because they work really well at keeping contamination rates low across different types of food manufacturing operations.

X-ray inspection systems designed for industrial use work best in environments that require processing large volumes quickly while still catching contaminants across all sorts of materials. Manufacturers often adjust these systems to look specifically for certain types of foreign matter depending on what they're producing, which helps get accurate readings every time. Factory workers and quality control managers regularly point out how these machines keep running efficiently throughout long shifts without slowing down production lines. That reliability makes them essential equipment for keeping products safe and up to standard. The real advantage shows up in industries such as electronics manufacturing and car part assembly, where even tiny flaws can cause major problems later on down the line.

X-ray systems for detecting foreign bodies in food are really good at finding all sorts of unwanted stuff in thick food products like meat or pasta. These machines process images on the fly so they can give immediate results, which means production lines don't have to stop as much when something gets detected. Industry insiders point out that keeping these systems updated is pretty important if manufacturers want to maintain accurate detection rates as time goes on. Putting these X-ray detectors into operation does more than just speed things up it helps companies meet those strict food safety regulations that keep getting tighter every year.